المنتجات

انقر للدردشة عبر الإنترنت

مشروع

انقر لترك رسالة عبر الإنترنت

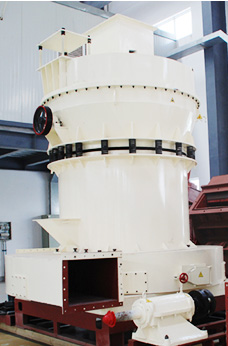

مشروع طحن الحجر الجيري بقدرة 20 طنًا في الساعة في أكتاو، كازاخستان

القدرة: 10-20 طن/ساعة

دقة المنتج النهائي: 50 ميكرون؛ 70 ميكرون؛ 100 ميكرون؛ 150 ميكرون

المعدات: مجموعتان من مطحنة الطحن MTW145G النسخة الأوروبية

Gansu Jiayuguan Iron Machining Powder Milling Equipment

Our Contact JISCO JUDE

Jiuquan Iron Steel (Group) Co LTD Corporate Headquarters #12 Xiongguan Road, Located in the Gansu province of northwest China, JISCO's iron and steel products include Jiuquan Iron And Steel (Group) Co,Ltd Dun BradstreetJiuquan Iron Steel Group Limited Company (hereinafter JISCO), founded in 1958, has Home JISCO JUDEGansu Jiuquan Iron and Steel Group Hongxing Iron and Steel Co, Ltd is a listed subsidiary of Jiuquan Iron And Steel(group) Co,Ltd

Jiuquan Iron Steel (group) Co Ltd, 12 Xiongguan Donglu

Looking for new B2B Leads ? Purchase a Company list with the executives and contact details Jiuquan Iron Steel (Group) Co Ltd (JISCO) is a Chinese company established in 1958 in Jiuquan Iron Steel (Group) Co, Ltd (JISCO) BNamericasLocated at the western end of the Great Wall of the Ming Dynasty (13681644), in Jiayuguan Jiuquan Iron and Steel Corporation2019年7月9日 Jiuquan Iron and Steel Corporation [Photo/jiugang] Located at the Jiuquan Iron and Steel Corporation

Find Metalworking Machinery Manufacturing Companies in

Find detailed information on Metalworking Machinery Manufacturing companies in Jiayuguan, 2012年5月1日 Target jet milling was used for the first time to convert cast iron scraps to powder An experimental apparatus was designed which comprised a compressor, a mixing section, a nozzle, an impact Production of grey cast iron powder via target jet milling2024年5月30日 Iron alloys powder refers to powder metallurgy forms of iron mixed with alloying elements like nickel, chromium, manganese, and carbon Iron powder metallurgy allows the manufacture of parts and components with Iron Alloys Powder: A Complete Guide Powder 2023年6月27日 Mendonça et al investigated the influence of milling duration, balltopowder ratio (20:1), and milling rotational speed on the production of recycled stainless steel powder from machining chips They employed a complete factorial design technique to optimize the ball mill conditions and found that these specific parameters led to a small particle size of 135 µm and Producing Metal Powder from Machining Chips Using Ball Milling

.jpg)

Cast Iron CNC Machining Milling Cast Iron Mountain Machine

We’ll cover what cast iron CNC machining is, the advantages of CNC machining for cast iron parts, finishes available for cast iron parts and more Whether you’re looking for advice on which service is right for your project or tips on how to get started, we’ve got you covered2023年10月8日 Iron alloys powder refers to powder metallurgy forms of iron mixed with alloying elements like nickel, chromium, manganese, and carbon Iron powder metallurgy allows the manufacture of parts and components with controlled density, porosity, strength, magnetic and other properties by compacting and sintering ironbased powder mixesIron Alloys Powder: A Complete Guide Additive Manufacturing In the pursuit of achieving zero emissions, exploring the concept of recycling metal waste from industries and workshops (ie, wastefree) is essential This is because metal recycling not only helps conserve natural resources but also requires less(PDF) Producing Metal Powder from Machining Chips Using Ball Milling 2021年6月1日 A framework for effective and clean conversion of machining waste into metal powder feedstock ball milling (BM) The efficacy SS, CI, Cu, Brass 1500 – 5000 Forging Ø 100170 Equipment A framework for effective and clean conversion of machining

Characterization and comparison of gray cast iron powder

Green compacts were made at the compacting pressures of 500, 600, 700 and 800 MPa Jet milled powder showed good compaction behavior while ball milled powder showed very poor compressibility Also, balanced compacts composed of 50% Hoganas SC10026 iron powder and each of the cast iron powders produced in this work were made at 500 and 8002017年9月1日 Request PDF Production of CuSn10 bronze powder from machining chips using jet milling In this study, an experimental target plate jet mill was designed and used to produce CuSn10 bronze powder Production of CuSn10 bronze powder from machining chips using jet milling2011年9月1日 There has been a number of studies in recent years regarding production of cast iron powder from machining swarf by milling technology (da Costa et al, 2003;Fawcett, 1978; Characterization and comparison of gray cast iron powder The steel industry boasts an annual production capacity of 1105 million tons of crude steel (including 12 million tons of stainless steel) The nonferrous industry possesses a production capacity of 17 million tons of electrolytic aluminum, Jisco JISCO JUDE

Sintering of grey cast iron powder recycled via jet milling

2013年5月1日 Porous grey cast iron powder metallurgy parts were made from grey cast iron powder manufactured via target jet milling of machining scraps The powders were used in the asmilled state without any Why Jiayuguan Pass So Important? Jiayuguan Pass used to be the starting point of the ancient Great Wall built during Ming Dynasty (1368 – 1644) It was the most important military defensive project guarding the far northwestern area of Jiayuguan, Jiayu Fort, Jiayuguan Great Wall History, Find Powder Milling Equipment related suppliers Carbon / Graphite, Ceramics, Coatings / Paint, Metals / Elements, Ferrous / Iron Based (Steel, Stainless), Nonferrous, Noble / Precious Metal Machine Shop Fabrication Equipment CNC Machining Centers CNC Turning Centers CNC Horizontal Boring Mills Vertical Horizontal Milling Machines Powder Milling Equipment Products Suppliers GlobalSpec2018年10月1日 Similarly (Abdollahi et al, 2013), produced grey cast iron powder from grey cast iron scraps using highenergy milling process As compared to Ø 25 balls, there is ~98% reduction in stress Twostage ball milling of recycled machining chips to create an

.jpg)

Sintering of grey cast iron powder recycled via jet milling

2013年5月1日 Grey cast iron powder was manufactured by recycling pearlitic grey cast iron machining scrap (Fig 1) via target jet milling The chemical composition of the scrap material is reported in Table 1 The size range of the scraps was within 30 to 12 mesh (600–1700 μm)2021年5月24日 The coating material of a tool directly affects the efficiency and cost of machining malleable cast iron However, the machining adaptability of various coating materials to malleable cast iron has been insufficiently researched In this paper, turning tests were conducted on cemented carbide tools with different coatings (a thick TiN/TiAlN coating, a thin TiN/TiAlN HighSpeed Machining of Malleable Cast Iron by Various 2021年4月4日 Milling cutters are important in the milling process The milling cutter can come in several different styles, but they are built for highspeed cutting The dovetail milling cutter is great when it comes to handling both vibration and shock while working on a part The dovetail milling cutter is attached to the milling machine 2020 Essential Milling Machine Tools Equipment Journeyman Used Crown Iron Works, Model 48, Milling Ring Flash Drying System Factory Direct Sale Stone Powder Milling Machine Price Limestone Grinding Mill Applications of grinding mill is designed to get fine and super fine Test, Lab, Medical equipment Back Textile and leather manufacturing Back Trucks Back Waste Recycling Used Powder Milling for sale IKA equipment more Machinio

Gansu Xiyu Xiongguan Mechanical Equipment Co, Ltd

Find company research, competitor information, contact details financial data for Gansu Xiyu Xiongguan Mechanical Equipment Co, Ltd of Jiayuguan, Gansu Get the latest business insights from Dun BradstreetJiuquan Iron and Steel Corporation [Photo/jiugang] Located at the western end of the Great Wall of the Ming Dynasty (13681644), in Jiayuguan city, Gansu province, Jiuquan Iron and Steel Corporation (JISCO) was founded in 1958 and was the fourth steel industrial base planned by China after Anshan, Wuhan and BaotouJiuquan Iron and Steel CorporationNowadays the machining centers are full of CNC milling equipment that are more efficient, highly accurate, and safe to use They are also great for special designs, dimensions, and materials, for micro machining as well as for large and heavyduty operations But you can still find manual and semiautomatic technology for lowcomplexity shapesIndustrial Milling Equipment MakingSemantic Scholar extracted view of "Production of grey cast iron powder via target jet milling" by M Ghambari et al In this study, jet milling was used to recycle tin bronze machining chips into powder The main purpose of this study was to assess the effect of the microstructure of tin bronze machining chips on Expand 4Production of grey cast iron powder via target jet milling

Jiayuguan Shuanghe Mechanical Equipment Co, Ltd Dun

Find company research, competitor information, contact details financial data for Jiayuguan Shuanghe Mechanical Equipment Co, Ltd of Jiayuguan, Gansu Get the latest business insights from Dun BradstreetFind company research, competitor information, contact details financial data for Gansu Yigong Jingyi Light Alloy Aviation Equipment Co, Ltd of Jiayuguan, Gansu Get the latest business insights from Dun BradstreetGansu Yigong Jingyi Light Alloy Aviation Equipment Co, LtdFind company research, competitor information, contact details financial data for Gansu Delichen Mechanical Electrical Equipment Co, Ltd of Jiayuguan, Gansu Get the latest business insights from Dun BradstreetGansu Delichen Mechanical Electrical Equipment Co, Ltd2013年5月1日 Grey cast iron powder was manufactured by recycling pearlitic grey cast iron machining scrap (Fig 1) via target jet milling The chemical composition of the scrap material is reported in Table 1 The size range of the scraps was within 30 to 12 mesh (600–1700 μm)Sintering of grey cast iron powder recycled via jet milling

Characterization and comparison of gray cast iron powder

2011年9月15日 The cast iron scrap investigated in this study was pearlitic lamellar gray cast iron (Fig 1) obtained during the dry machining of slabs used for making car engine componentsThe chemical composition of this material is reported in Table 1The size of the scraps used was in the range − 12 + 30 meshPlanetary ball milling and target jet grinding were used to pulverize scraps2011年9月15日 Two different pulverizing methods have been used to produce powder from gray cast iron machining scrap Target jet milling proved to be a preferred method compared to planetary ball mill as the powders produced by the former did not need any post pulverizing treatment such as annealing and had superior green propertiesCharacterization and comparison of gray cast iron powder Find company research, competitor information, contact details financial data for Jiayuguan Ruilong Mechanical Equipment Co, Ltd of Jiayuguan, Gansu Get the latest business insights from Dun BradstreetJiayuguan Ruilong Mechanical Equipment Co, Ltd Dun2012年5月1日 Target jet milling was used for the first time to convert cast iron scraps to powder An experimental apparatus was designed which comprised a compressor, a mixing section, a nozzle, an impact Production of grey cast iron powder via target jet milling

Iron Alloys Powder: A Complete Guide Powder

2024年5月30日 Iron alloys powder refers to powder metallurgy forms of iron mixed with alloying elements like nickel, chromium, manganese, and carbon Iron powder metallurgy allows the manufacture of parts and components with 2023年6月27日 Mendonça et al investigated the influence of milling duration, balltopowder ratio (20:1), and milling rotational speed on the production of recycled stainless steel powder from machining chips They employed a complete factorial design technique to optimize the ball mill conditions and found that these specific parameters led to a small particle size of 135 µm and Producing Metal Powder from Machining Chips Using Ball Milling We’ll cover what cast iron CNC machining is, the advantages of CNC machining for cast iron parts, finishes available for cast iron parts and more Whether you’re looking for advice on which service is right for your project or tips on how to get started, we’ve got you coveredCast Iron CNC Machining Milling Cast Iron Mountain Machine 2023年10月8日 Iron alloys powder refers to powder metallurgy forms of iron mixed with alloying elements like nickel, chromium, manganese, and carbon Iron powder metallurgy allows the manufacture of parts and components with controlled density, porosity, strength, magnetic and other properties by compacting and sintering ironbased powder mixesIron Alloys Powder: A Complete Guide Additive Manufacturing

(PDF) Producing Metal Powder from Machining Chips Using Ball Milling

In the pursuit of achieving zero emissions, exploring the concept of recycling metal waste from industries and workshops (ie, wastefree) is essential This is because metal recycling not only helps conserve natural resources but also requires less2021年6月1日 A framework for effective and clean conversion of machining waste into metal powder feedstock ball milling (BM) The efficacy SS, CI, Cu, Brass 1500 – 5000 Forging Ø 100170 Equipment A framework for effective and clean conversion of machining Green compacts were made at the compacting pressures of 500, 600, 700 and 800 MPa Jet milled powder showed good compaction behavior while ball milled powder showed very poor compressibility Also, balanced compacts composed of 50% Hoganas SC10026 iron powder and each of the cast iron powders produced in this work were made at 500 and 800Characterization and comparison of gray cast iron powder 2017年9月1日 Request PDF Production of CuSn10 bronze powder from machining chips using jet milling In this study, an experimental target plate jet mill was designed and used to produce CuSn10 bronze powder Production of CuSn10 bronze powder from machining chips using jet milling

.jpg)

Characterization and comparison of gray cast iron powder

2011年9月1日 There has been a number of studies in recent years regarding production of cast iron powder from machining swarf by milling technology (da Costa et al, 2003;Fawcett, 1978;